POWERply roof membranes offer the best granule adhesion in the roofing industry. It gets this reputation with its colors, standard white or ultra- white, that are used for Energy Code compliance. To add on to its durability, its fire rated surfacing provides for the safety of those inside the building.

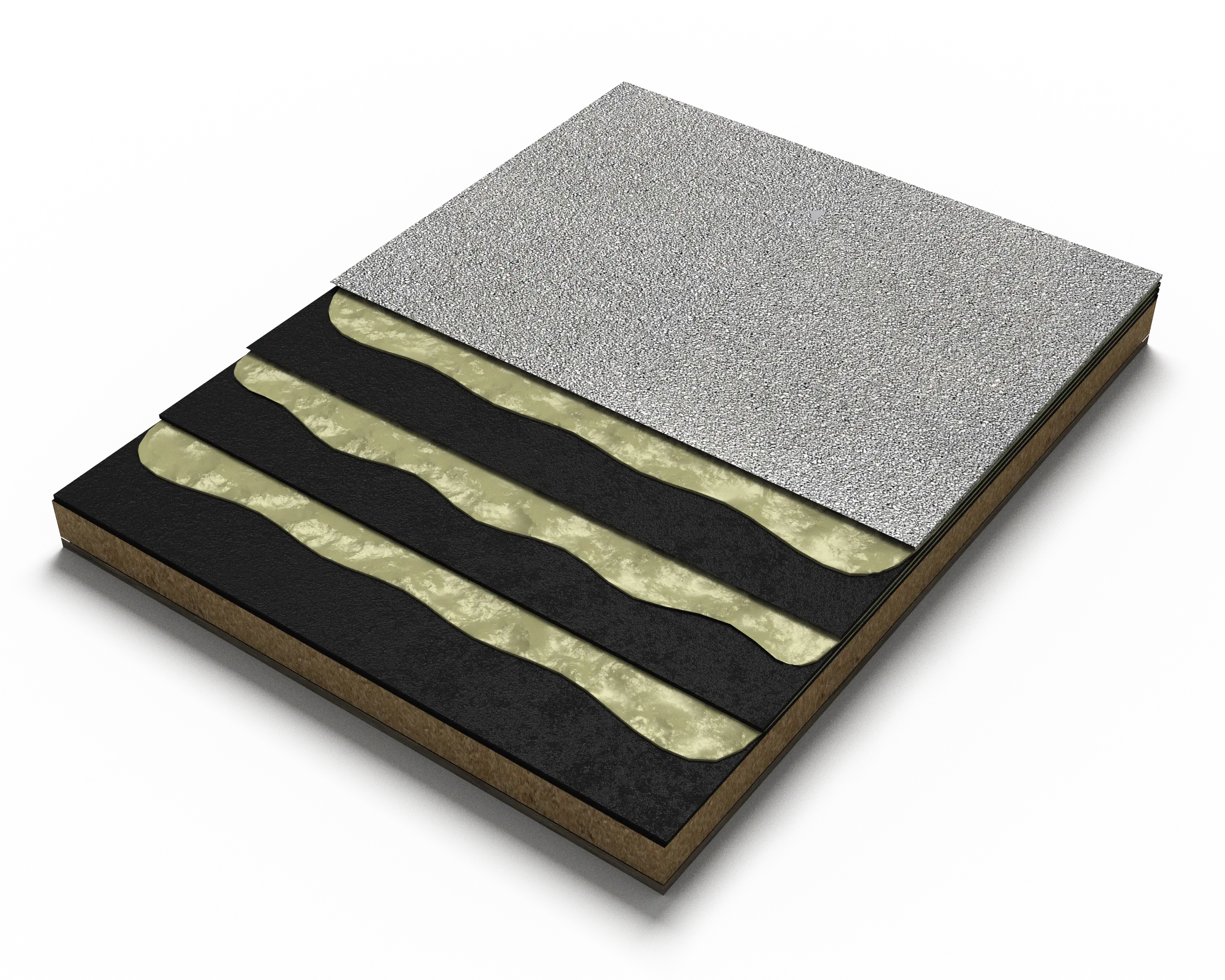

POWERply MB membranes are constructed using specialized fabrics selected for their unique features and benefits. Several POWERply brands are based on fiberglass reinforcing mats, which offer strength and long term stability to the finished roof membrane. Other POWERply brands are manufactured using polyester, which provides puncture resistance along with an exceptional mix of tensile and elongation which exceed industry specifications for roof system performance. The top performing POWERply membranes utilize an engineered combination of fiberglass and polyester, which combines the performance advantages of both fabrics to provide the best long term roof membrane performance with the capability of extending its service life with the application of fluid applied restoration systems in the years to come.

The POWERply system is best when fully adhered with Tremco POWERply Endure BIO Adhesive, which is Tremco’s cold applied, ultra-low odor, solvent- free, fast curing, watertight membrane adhesive. POWERply membranes may also be applied with traditional hot applied bituminous adhesives, such as Tremco THERMastic SEBS Modified Asphalt. These membrane adhesives enable POWERply roof systems to resist the uplift pressures generated during exposure to high winds.